IN THE FIRST OF A NEW SERIES IN WHICH WE SCRUTINISE THE GREEN CREDENTIALS OF SOME OF THE LEADING OUTDOOR BRANDS, WE TALK TO VAUDE ABOUT THE GERMAN COMPANY’S SUSTAINABILITY POLICIES…

VAUDE have long been known as one of the most forward-thinking outdoor brands when it comes to sustainability, but are they any different to other companies that tout their green credentials – and – if so, how? And what does it even mean to be ‘green’ in 2019, how can a company’s ‘greenness’ be measured, and – considering the outdoor apparel industry is miniscule compared to the wider clothing industry – will any of it make any difference in the bigger scheme of things anyway? These and other questions we put to VAUDE’s sustainability guru, Hilke Patzwall, when we spoke to her recently…

VAUDE first adopted an ‘environment first’ philosophy in 2009 – how and why did that come about?

When our CEO Antje von Dewitz prepared to take over the company from her father, she and a core team of employees decided to focus the entire company on doing sustainable business. We were all very committed, but we were not sure how far we would get with it – taking into account that at that time sustainability topics were not at all discussed in our industry, and VAUDE of course depends on economic success. But we went for it anyway. As a first milestone we had the company EMAS certified in 2008. That gave us a very good framework on environmental aspects we need to work on, guidance to organize, and a 3rd party verified report to publish.

What were the initial aims of the strategy, and how has it changed over the years?

The strategy was from the start to change the entire company to becoming a sustainable business. The strategy has never changed since, but the goals and KPI’s we set to measure progress have evolved and become a lot more ambitious, specific, and holistic over the years.

What sets VAUDE apart from other companies that promote their sustainable credentials?

AT VAUDE, we fully integrate sustainability into everyday business life. It’s not any separate department, but each and every job in the company considers eco and social aspects right away whenever a decision is made. That makes VAUDE special and differentiates us from most other companies in the industry.

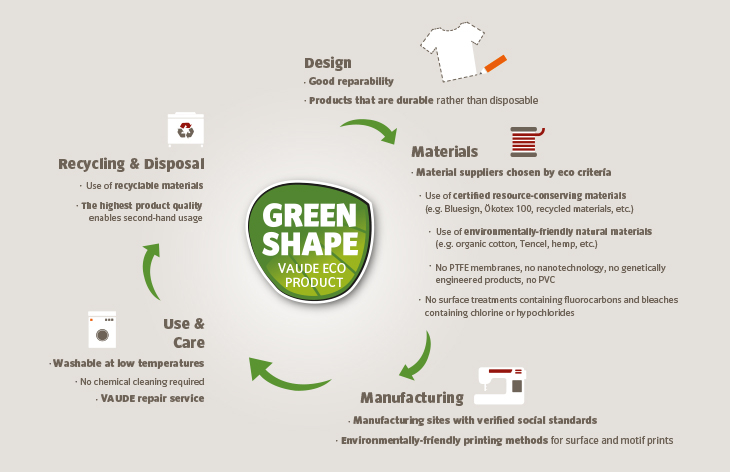

Green Shape is VAUDE’s own standards for production of their products

You created your own set of standards – Green Shape – in 2010; where can readers find out about this?

https://csr-report.vaude.com/gri-en/product/greenshape-concept.php

How does Green Shape 2.0 take the idea further, and is it inevitable there will be a Green Label 3.0, 4.0 etc?

We are currently working on Green Shape 3.0. That will close the gaps within the product life cycle we have not set criteria for yet: repairability, material efficiency, end of product life criteria, and third party verification. The Green Shape standard moves along with new technologies, materials, and certifications coming up. You can view the (current) Green Shape 2.0 criteria here: https://csr-report.vaude.com/gri-en/product/greenshape-concept.php.

Should the move towards sustainable products be driven by consumers, governments, brands… or all three?

We believe it’s the industry’s responsibility to make products under decent eco and social conditions, that last a long time, and can be repaired and recycled. As a brand, you should not need anyone to force you by law to take that responsibility seriously. Still, VAUDE supports the implementation of strict legal regulation on sustainability issues – be it chemicals, labour standards, climate protection or biodiversity; that would create a level playing field for all brands in the market, instead of now where companies that invest in sustainability are less profitable. So we encourage governments to take action, like the German Government did recently with creating the meta label Grüner Knopf which VAUDE has adopted as one of the first brands. Consumers play an important role in fighting over-consumption, but they can never be made responsible for brands’ sourcing decisions, for example.

Which industry-wide standards are the most important right now, and in which areas are new or better standards most needed?

For labour standards – Fair Wear Foundation

For chemical management – bluesign and ZDHC

For natural fibres – GOTS

For down products – RDS

For products with recycled materials – GRS

For transparency – hopefully soon the Higg Product Tools!

In Germany in addition the Grüner Knopf has set a new benchmark on sustainability labelling.

How do you reconcile the concept of making products last a long time and consumers consuming less, with the necessity as a business for growth?

This is probably the biggest challenge for the entire industry. We need to change business models, away from ‘fast’ products to products that are built to serve for a long time, accompanied by new services for retail and consumers. VAUDE has made first steps into that direction with our rental service, washing, re-impregnating and repair services, and the Second Use platform on eBay. Questioning the need for eternal growth is one of the core topics of the Economy for the Common Good of which VAUDE is one of the pioneer companies.

VAUDE’s SECOND USE INITIATIVE HELPS FIND A HOME FOR USED GEAR

How hard is it to remain competitive with the standards you set yourself?

Very hard. As I said above, it would be much more fair in the market if all competing brands would care the same about people and environment.

Are there any particular fabrics/materials that are hard to produce in an environmentally-friendly manner?

Waterproof materials without fluorocarbons might be the most widely-known challenge. But there are a lot more potentially harmful substances that need to be phased out of usage in outdoor industry which is a long painful process for fabric mills in terms of production process, quality, and cost. Another example are PVC free bags and bike panniers. We managed to switch to PVC free materials a few years ago, but we invested hugely into knowhow, testing, and production technologies. Also, all the different third party certifications we require of our supply chain not only add to the cost of the product but limit the choice of materials and suppliers available.

Is replacing these materials (such as using wood cellulose in fleece products to reduce harmful microplastics, as you already do) the solution?

It is a first step for a possible solution, but there is a lot more research needed in the entire industry. We need to use a lot more renewable or recycled materials in general.

How much of your manufacturing takes place in Germany, and how much overseas?

Please see HERE.

Is it possible to manufacture technical clothing in Europe, or does the low costs and expertise in Asia now make that unrealistic?

Manufacturing/cost of work is an issue in Europe, but even more it’s that most technical fabrics are made in Asia which makes production in Europe difficult. See HERE for figures on countries our materials come from.

Do you take into account the cleanness of energy used in the countries in which you manufacture (e.g. France is nuclear, so in terms of greenhouse gases it is cleaner energy than, say, China, where it is mostly coal powered)?

VAUDE is in the process of setting science-based targets in order to contribute our measurable share to climate protection which includes scope 3 emissions from our supply chain. That involves energy efficiency and renewable energies in the supply chain as well as in headquarters and our Made in Germany production (where we have been using 100% renewable electricity since 2009). We discuss energy efficiency and renewable energy usage with our suppliers and support them making progress in both areas. We are part of a project of WWF and German GIZ in Vietnam which addressed exactly these topics with some pilot suppliers.

the challenge for us all is to enjoy the outdoors without harming it

You have mentioned diversifying the business in the future to other areas such as clothing repair; can you tell us more about this?

See question on new business models and post growth strategies above. We believe that all companies have to deal with this topic sooner or later. So we try to explore alternative business models which do not rely on selling more new products forever. Renting is just one example.

Being a privately-owned company allows you to pursue your sustainability agenda (it’s perhaps no coincidence that Patagonia is also privately owned) – in your opinion, is it impossible for a listed company (where shareholders demand maximum profits) to operate at a similar level in this respect?

It´s probably a lot more challenging to explain the benefit of long-term thinking to shareholders used to thinking in short-term profits. Still, it’s not impossible at all; it’s just a matter of becoming aware of your responsibility as a relevant part of the system and starting the process by setting and pursuing goals, no matter who owns the company or how large it is. This is what the world community agreed on by setting the UN Sustainable Development Goals.

What can Trek & Mountain readers do to reduce their environmental impact when buying/owning outdoor gear?

There are some practical ideas HERE – also of course, vote for the political parties that support sustainability to help integrate environmental protection and fair labour into society.

More info on VAUDE’s sustainability policies and products at: www.vaude.com