Fabric specialist Polartec has launched a new fabric called Power Air, which has been engineered specifically to reduce the shedding of fibres into the environment and waterways in particular and contribute to the growing issue of microplastic pollution.

Conventional fuzzy fleece fabrics with exposed fibres inevitably shed tiny particles during general wear and washing in particular. It’s a recognition by Polartec of the huge ecological issue of plastic micro-particles being released into the environment particularly during laundering.

To combat that, the brand spent thousands of hours developing a newly engineered fabric that it says is ‘proven to shed five times less than other premium mid-layer weight fabrics’.

The resulting material – already being used by adidas for its Power Air Hoody – www.adidas.co.uk – is quite different from conventional fleece.

The resulting material – already being used by adidas for its Power Air Hoody – www.adidas.co.uk – is quite different from conventional fleece.

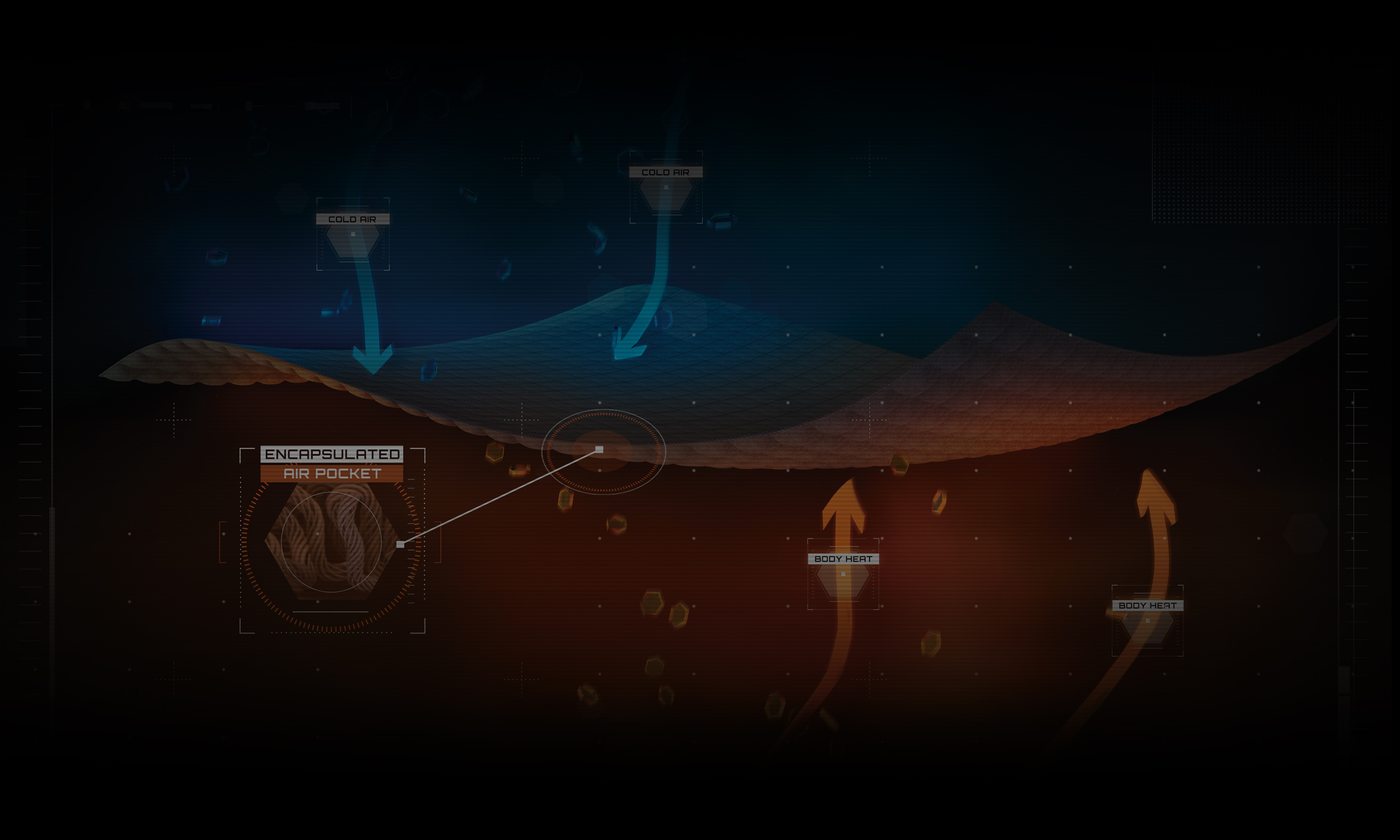

There’s an internal grid structure, which the company says is not unlike ‘fabric bubble wrap’ – no, you can’t pop it, teamed with a smooth outer face that resists pilling and is claimed to increase durability. The insulating fibres are basically encased within the knitting process, but are still able to do their job of trapping air and keeping you warm.

Technically, the insulating air is – it says here – ‘encased with a continuous yarn’.

Technically, the insulating air is – it says here – ‘encased with a continuous yarn’.

It’s fascinating stuff and meant Polartec had to develop a whole new testing protocol to allow them to measure the amount of fabric fibres lost to shedding during domestic laundering. The test simulates multiple washing machine cycles in a single process with before and after weighing allowing an assessment of how much fibre has been shed.

It’s ground-breaking work in fabric engineering and has already been recognised by the World Textile Information Network with its Future Textile Award for Best Innovation: Sustainable Textiles.

And while it’s initially being debuted as midlayer fleece – Mammut and Houdini are due to release Power Air products shortly – the technology is also applicable to next-to-skin baselayer fabrics and ‘extreme weather protection ones’.

And while it’s initially being debuted as midlayer fleece – Mammut and Houdini are due to release Power Air products shortly – the technology is also applicable to next-to-skin baselayer fabrics and ‘extreme weather protection ones’.

The outdoor clothing industry is responsible for only a small percentage of microplastic pollution due to fabric fibre shedding, but it’s great to see Polartec continuing it’s ecologically-aware developments in this area. In the past it’s been a leader in recycling plastic into fabrics and recently announced its 100% recycled Power Fill synthetic insulation.

Bottom line, the new Power Air fleece may not feel as soft and snuggly as traditional fleece, but it promises to be a whole lot better for the environment. Watch this space for some actual user impressions.

More information at www.polartecpowerair.com