Jon Doran reports from a special event at Aviemore on the introduction of GORE-TEX’s new, more sustainable, membrane.

GORE-TEX, probably the world’s best-known waterproof and breathable fabric, is changing. By autumn 2025 the brand’s decades-old ePTFE technology will be replaced by a brand new, more eco-friendly alternative called ePE. On the one hand it’s a huge change, a bit like Cadburys suddenly switching from using dairy to oat milk in its chocolate (don’t worry, they’re not doing that) – on the other, Gore’s hope is that walkers and climbers using technical clothing made from its fabrics won’t notice at all. They’ll still be just as waterproof, breathable and durable as existing GORE-TEX garments.

So what’s going on? Trek & Mountain was part of a select group of outdoor journalists invited up to an autumnal Aviemore in the Scottish Highlands for an insight into the brand’s quiet revolution and to try out some of the first technical mountain kit made from NEW GORE-TEX.

ePE Gore-Tex looks and feels no different to existing ePTFE Gore-Tex

It’s a sandwich…

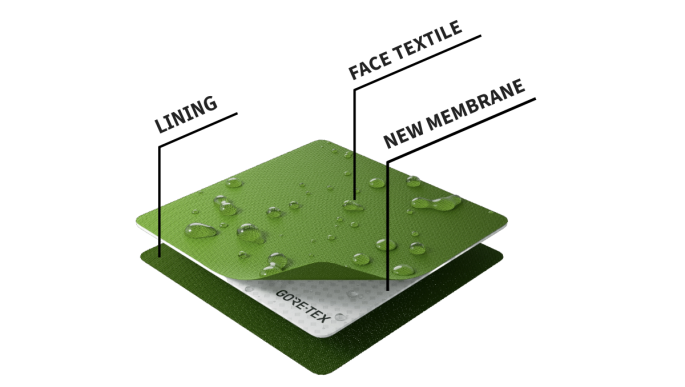

First, some basic stuff. Gore has used its original, ePTFE – it stands for expanded polytetrafluoroethylene and is the same stuff used to make Teflon non-stick pan coatings – since the 1970s. It’s a filmy, thin, white membrane that gets sandwiched between two layers to create GORE-TEX waterproof fabrics and it’s been that way ever since. Over the years the construction and fabrics have been refined and tweaked to make them more breathable or lighter or more durable, but that ePTFE membrane has been ever-present.

Unfortunately though, the production of the ePTFE membrane involves the use of potentially environmentally-harmful fluoro-chemicals (PFCs), which is why Gore has spent the last 10 years working on an alternative membrane made from expanded Polyethylene/a Polyolefin (ePE), which can be produced without the use of those chemicals and has a lower carbon footprint than ePTFE. The pores in the new membrane are made by a stretching process rather than by using PFCs. The first garments using the new technology were launched in 2021, but it’s only this year that a small number of technical outdoor lines using the new membrane have quietly appeared in the shops. The big deal though, is that within two years all GORE-TEX garments will use the ePE fabrics, which is a huge undertaking.

The diagram may look familiar, but beneath the surface there’s major changes

What does it all mean?

Hopefully, if you’re hunkered down in a Cairngorm blizzard or braving a miserably wet Lake District mountain day, Gore hopes the fabric will be just the same. It’ll still have a minimum hydrostatic head of 30,000mm, so it’ll be waterproof and it will, says Gore, be just as durable as current fabrics. What’s less clear right now, is how it’ll compare in terms of breathability, how it’ll cope with transmitting heat and water vapour outwards. Gore were slightly coy about this, offering no figures or commitments. Reading between the lines, we’d guess that it’s an ongoing process. The reason GORE-TEX fabrics like PRO or ACTIVE are more breathable than the bog-standard version is in the way they’re manufactured and, in particular, how the inner and outer fabrics are bonded to the waterproof membrane. It’s not an unreasonable assumption that the new membrane may behave slightly differently to the original version, and it may take time to tweak its production to achieve the same qualities. So right now, the breathability jury is still out.

There are several brands already using ePE-based GORE-TEX for a small number of lines available in the UK – notably Mountain Equipment, Patagonia and Rab – and we were kitted out with ME Makalu Jacket and Pants in preparation for a couple of days biking and hiking with mindful outdoor guides Wandering Workshops led by ex-Olympic snow boarder Lesley McKenna. At first glance, there’s no obvious visible or tangible difference between the Makalu and an equivalent ePTFE-based GORE-TEX shell. The jacket has the same excellent ME Alpine cut and features as, say, a Lhotse, and the fabric itself feels much the same as any other standard – i.e. not PRO or ACTIVE – three-layer Gore-Tex shell. What you might notice with the Makalu and other ePE jackets is a distinctive hang-tag made using sugarcane waste, known as Bagasse, which appears as brown paper and lists the garment’s sustainable features. In addition to the ePE membrane, these include the use of fabrics with are either entirely or partly made from recycled materials and have been ‘solution dyed’, a process which means colour is incorporated into the yarn during manufacture rather than being applied as a conventional dye. In the case of the Makalu, that means a 100% recycled Polyester face fabric with a solution-dyed tricot backer.

Testing the Mountain Equipment Makalu Jacket, featuring the new membrane, near Aviemore

First impressions

We’re big fans of Mountain Equipment’s shell jackets. They have an excellent cut mixing a neat fit – no flappy fabric – with excellent mobility, a first rate mountain hood, handy pit-zips and enough pockets to accommodate most needs, so no surprises on that front. What we can also tell you is that based on several months’ of autumn/winter use so far, both in the Cairngorms and the Peak District, the jacket works just as well as any other standard GORE-TEX jacket we’ve tested. So far it’s kept us reliably dry and for walking use with a relatively steady output at least, it’s been breathable enough to avoid sudden outbreaks of boil-in-the bag syndrome. It’s clearly not quite as breathable as GORE-TEX PRO, but then it isn’t meant to be.

One disappointment is the performance of the durable water repellent finish (DWR), which rapidly suffered from contamination in regularly handled areas like the cuffs, and simply stopped beading water, but that’s pretty standard for modern PFC-free DWRs. Interestingly the face fabric is Polyester rather than Nylon, which is generally reckoned to be harder wearing, but less straightforward to produce in recycled form. We’ll be keeping an eye on high-wear areas over winter and report back. So in short, so far, so good, watch this space.

Future fabrics

As we understand it, by autumn 2025 pretty much all GORE-TEX fabrics including INFINIUM, which is going to be called WINDSTOPPER by GORE-TEX LABS from this winter, will be made from ePE-based fabrics. That includes both two and three-layer materials. One fabric set to disappear shortly is PACLITE and PACLITE PRO, which is being phased out from this winter, though you may still find limited supplies of PACLITE garments for another year or so – if you like the stuff, buy it soon is our advice. One other thing: care procedures for the new GORE-TEX fabrics remain the same, though it’s worth taking note that Gore now suggests that heat-treating garments will help optimise DWR performance.

There’s no mention of ePE anywhere on the jacket other than in the small print on the hangtags

What if you want an ePE-based garment now?

If you want a more sustainable, ePE-based GORE-TEX garment right now, there are a few options available in the UK right now. We’ve already mentioned the Mountain Equipment Makalu Jacket and Pant available for both men and women, but ME also has a two-layer, Nanda Devi hillwalking shell. Rab meanwhile, uses the new fabric in its men’s and women’s Namche GORE-TEX jacket, three-layer shells designed for hiking and hill walking use. Again the fabric uses recycled materials and a solution-dyed backer.

Adidas TERREX is on board with the XPLORIC GORE-TEX Rain jacket for both men and women. Finally, eco-ground breakers Patagonia are using the ePE GORE-TEX for their Triolet Jacket, a full-on technical alpine shell with a 100% recycled outer shell fabric with a tricot backer and manufactured in a Fair Trade Certified factory. All the garments above seem to use the same 75D Polyester face fabric and solution-dyed backer and are a ‘standard’ GORE-TEX; if you want the tougher, lighter PRO option or more breathable ACTIVE, you’ll have to wait for now, though Arc’teryx has launched a ePE fabric with the soft-feel C-KNIT backer technology this spring.

See a full review of the Mountain Equipment Makalu in issue 121 of Trek & Mountain.

Head to www.goretex.com for more info on the new ePE technology.

Comments

Get ready to use your washing machines more often for proofing guys

Yup that is a reality with all waterproof clothing that uses fluorocarbon-free DWRs – more washing and re-proofing is required than before!